but you can still purchase these products, or make further enquiries,

by calling VJ Technology on 01233 637695.

Thank you for your interest in our range.

Online orders are currently unavailable on this website

but you can still purchase these products, or make further enquiries,

by calling VJ Technology on 01233 637695.

Thank you for your interest in our range.

Online orders are currently unavailable on this website

but you can still purchase these products, or make further enquiries,

by calling VJ Technology on 01233 637695.

Thank you for your interest in our range.

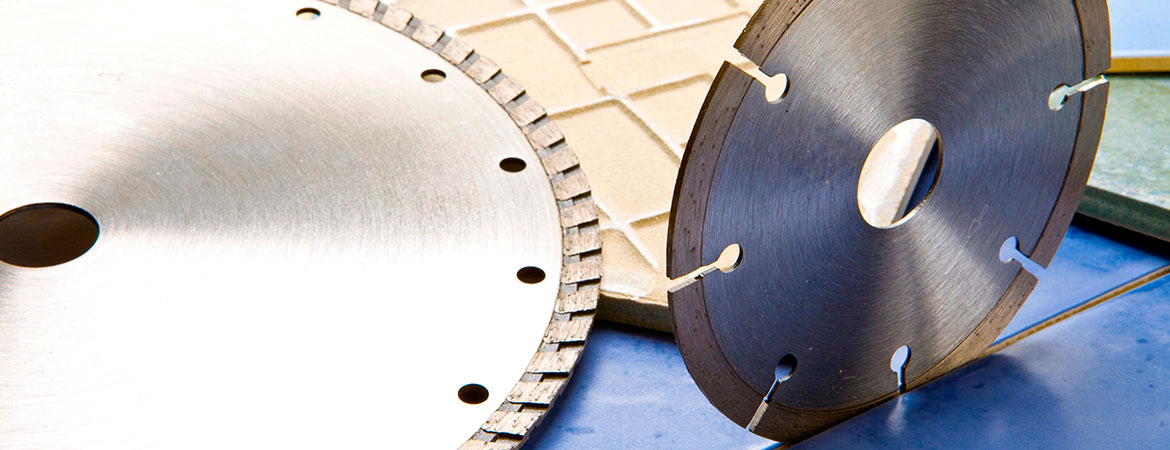

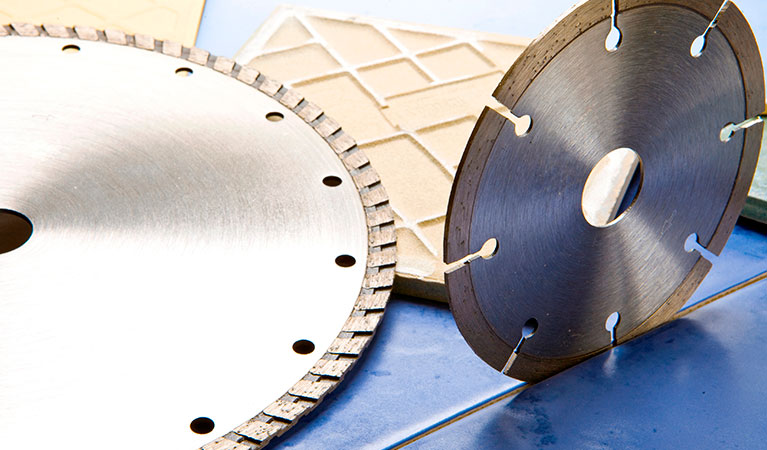

Classic Range

Quality blade, reliable performance

excellent value for money.

Premier Range

Enhanced performance double laser-welded

blades long segment life high diamond content

ideal when cost of cut matters most.

Significantly enhanced performance

Double laser-welded highest possible

diamond content high cutting speeds

exceptional performance for the

professional user.

Specialist Range

but you can still purchase these products,

or make further enquiries,

by calling VJ Technology on 01233 637695.

Thank you for your interest in our range.

Online orders are currently unavailable on this website

but you can still purchase these products,

or make further enquiries,

by calling VJ Technology on 01233 637695.

Thank you for your interest in our range.

but you can still purchase these products,

or make further enquiries,

by calling VJ Technology on 01233 637695.

Thank you for your interest in our range.