Concrete Cutting throws up a lot of dangerous dust. Stones, rocks, sands and clays contain large amounts of crystalline silica and are used to make kerbs, flags, bricks, tiles and concrete. Cutting these materials produces airborne dust containing very fine Respirable crystalline silica (RCS) particles. These particles are small and it is not always possible to see the RCS dust in normal lighting.

Serious health effects, such as lung cancer or silicosis, can result from exposure to RCS. This is because fine RCS particles can penetrate deep into the lungs. Silica is currently the second most important cause of occupational lung cancer after asbestos.

Serious health effects, such as lung cancer or silicosis, can result from exposure to RCS. This is because fine RCS particles can penetrate deep into the lungs. Silica is currently the second most important cause of occupational lung cancer after asbestos.

Silica causes a stiffening and scarring of the lungs called silicosis. This condition can make the affected person so breathless that they become disabled. Silicosis also increases the risk of serious lung infections such as tuberculosis (TB). This usually follows many years of exposure and is irreversible, but exceptionally high exposures over a few months or years can also be responsible.

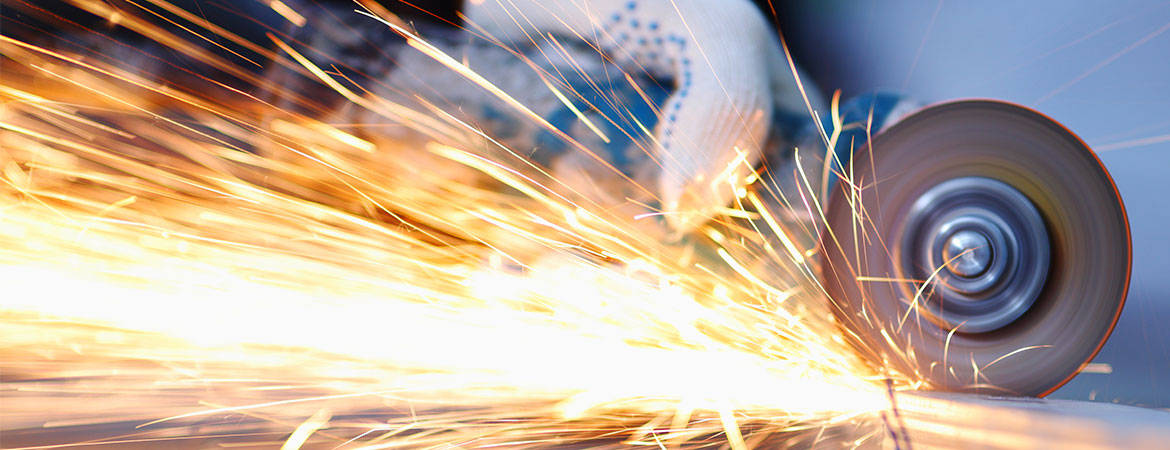

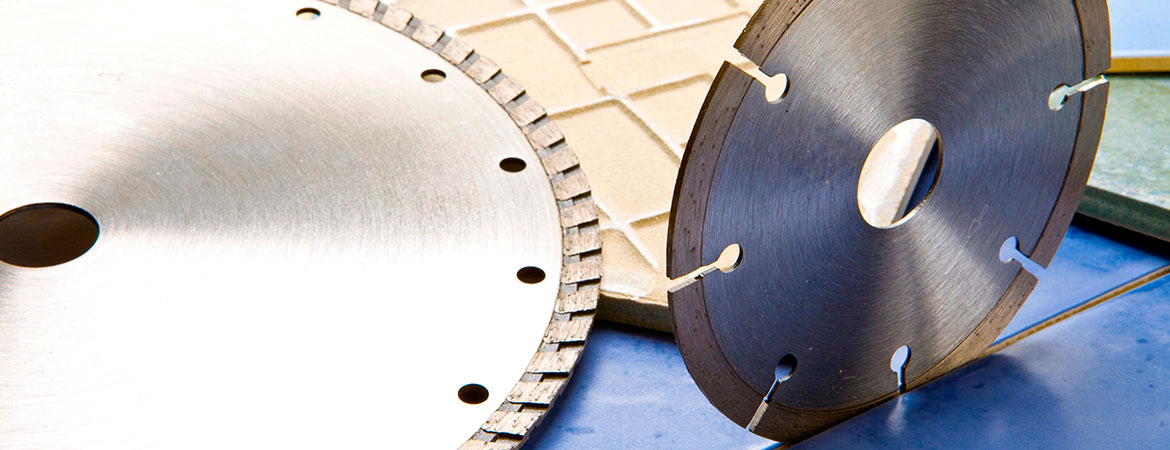

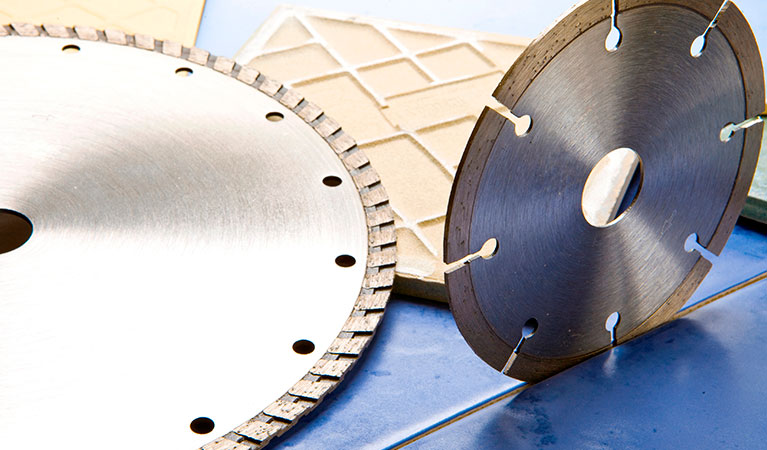

Blade selection is important! Diamond tip blades cut more quickly than abrasive wheels. Normally a blade with a diamond tip will cut a paving slab in about one minute. Choose the correct Diamond Cutting blade for the job.

https://www.globaldiamond.co.uk/application-finder

Consider the health and safety of the operator and of others when cut-off saws are used. Use suitable personal protective equipment (PPE), such as hard hats, eye protection and ear defenders. Make sure these items are worn correctly and are suitable for use together.