First ensure the object to be cut:

– is fully supported

– is secured so it cannot roll or slip off

– is prevented from vibrating.

ensuring that you are not endangered by the severed or separated part.

– how heavy the part is

– how it can move after separation

– whether it is under tension

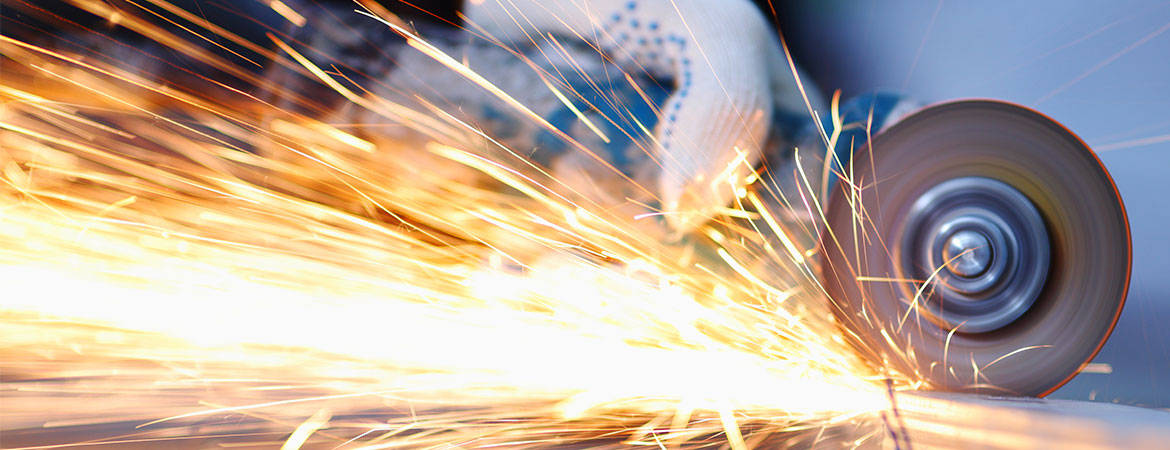

cutting wheel, always re-set the cutting wheel against the workpiece anew – the cutting depth for each operation should not exceed 5 to 6 cm. Cut thicker materials in multiple passes. Cut large wall thicknesses with even back and forth movements.